International Flender Graffenstaden gearbox repair

GBS Gearbox Services international is the fastest, full service, worldwide specialist in gearbox repair of Flender Graffenstaden gearboxes. Taking the latest innovations of our gearbox service experts, our goal is to get, often mission critical, gearboxes back into production at the shortest timespan possible. We have a winning track record in Flender Graffenstaden servicing! Having experience with a wide variaty of brands, we know the weakspots and strengths of any brand and can not only repair but often improve the reliability of any gearbox system.

Industrial gearbox services

Flender Graffenstaden is a manufacturer in the field of high speed enclosed gear drives. Flender Graffenstaden has supplied over 10,000 high speed gearboxes for the Petrochemical, Process and Power Generation industries around the world. Supplying gearbox systems on parallel shaft with horizontal offset, parallel shaft with vertical offset and Epicyclic types. All the Flender Graffenstaden gearboxes are being serviced by GBS Gearbox Services international.

GBS Gearbox Services international is specialised in services the gearboxes in all these industries, as our specialty lies in gearbox services. Our highly experienced emergency support experts work to provide effective solutions that meet your demands, getting your production running!

GBS Gearbox Services international is specialised in services the gearboxes in all these industries, as our specialty lies in gearbox services. Our highly experienced emergency support experts work to provide effective solutions that meet your demands, getting your production running!

2 different projects

- Type:

- TX40 / 4C

Scope of work:

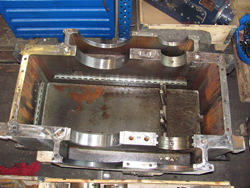

This gearbox is used for generator testing purposes and suffered extensive fire damage during one of these test run sessions.

Gearbox Services International was invited to establish the condition of the gearbox, in order to assess which parts can be salvaged, as well as to compile a scope of repair for bringing the gearbox back into service. During the inspection, the gearbox was completely dismantled.

Rated power gearbox : 2,500 kW

Rotational speed : 4,233 / 900 rpm

The following activities comprise the scope of this inspection:

- Exterior: visual inspection, appendages

- Casing: internal conservation, split surface flatness

- Bearings: visual inspection

- Shafts: runout (staightness), hardness, journal surface condition

- Gears: visual inspection, crack testing, hardness

- Labyrinths: visual for rubbing marks

Location - date:

The Netherlands - March 2011

- Type:

- TX61/1CV

Scope of work:

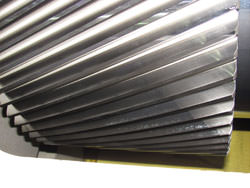

Preventive inspection of a Flender Graffenstaden, TX61/1CV, load gearbox.

The load gearbox is part of a LM6000 gas turbine driven generator set.

Scope of work:

Rated power gearbox : 70,000 HP

Rotational speed : 3,627 / 3,000 rpm

Scope of work:

- perform visual inspection of gears through the inspection cover

- check dynamic tooth contact pattern of double helical gear set

- check seals of installation for any oil leakages

- check gearbox casing leveling

- summarize findings in diagnostic report

Location - date:

Belgium - February 2011

For more than 20 years, GBS Gearbox Services has gained extensive knowledge of gear technology through new gearbox design and manufacture. Today, GBS is supplying service to Flender Graffenstaden gearboxes in marine and industrial markets.

Using this experience, our Services division will provide the highest level of commitment to existing and new customers for products already operating in the field.

Ship owners and Industrial companies throughout the world value the reassurance of the superior support provided by the skilled and dedicated engineering and technical specialists that form the GBS Gearsbox Services team.

Field Service Engineers are on constant standby to visit any ship or plant throughout the world. With an unrivalled average 25 years industry and marine experience, they are all fully qualified and certified to work in all environments, both on and offshore. Their high level of technical experience enables most work to be carried out on-site, supported by an practical experienced team of world-leading design and research engineers in the Netherlands.

Our Services team is qualified to inspect, maintain and repair any make or type of industrial or marine gearbox. Many working examples exist of improvements we have made to non-Flender Graffenstaden gearboxes, that have extended the life of the gearbox.

Using this experience, our Services division will provide the highest level of commitment to existing and new customers for products already operating in the field.

Ship owners and Industrial companies throughout the world value the reassurance of the superior support provided by the skilled and dedicated engineering and technical specialists that form the GBS Gearsbox Services team.

Field Service Engineers are on constant standby to visit any ship or plant throughout the world. With an unrivalled average 25 years industry and marine experience, they are all fully qualified and certified to work in all environments, both on and offshore. Their high level of technical experience enables most work to be carried out on-site, supported by an practical experienced team of world-leading design and research engineers in the Netherlands.

Our Services team is qualified to inspect, maintain and repair any make or type of industrial or marine gearbox. Many working examples exist of improvements we have made to non-Flender Graffenstaden gearboxes, that have extended the life of the gearbox.

We are working in the following markets

POWER:

Total Power Station gearboxes

Circulating Water Pump gearboxes

Boiler Feed Pump gearboxes

Coal Mill gearboxes

Wind turbine gearboxes

Hydro turbine gearboxes

Gas turbine gearboxes

Steam turbine gearboxes

Total Power Station gearboxes

Circulating Water Pump gearboxes

Boiler Feed Pump gearboxes

Coal Mill gearboxes

Wind turbine gearboxes

Hydro turbine gearboxes

Gas turbine gearboxes

Steam turbine gearboxes

OIL & GAS OFFSHORE - Oil rigs and FPSO’s

Turbine generator gearboxes

All Mechanical drive gearboxes

Boiler feed pump gearboxes

Sea water injection pumps gearboxes

Compressor gearboxes

Turbine generator gearboxes

All Mechanical drive gearboxes

Boiler feed pump gearboxes

Sea water injection pumps gearboxes

Compressor gearboxes

OIL & GAS ONSHORE / PETROCHEMICAL – Pumping and refineries

Turbine generator gearboxes

All Mechanical drive gearboxes

Boiler feed pump gearboxes

Pipeline pumping gearboxes

Pipeline compressor gearboxes

Turbine generator gearboxes

All Mechanical drive gearboxes

Boiler feed pump gearboxes

Pipeline pumping gearboxes

Pipeline compressor gearboxes

Marine

Propulsion gearboxes

Turbine generator gearboxes

Propulsion gearboxes

Turbine generator gearboxes

Heavy Industry

Sugar

Steel

Mining

Chemicals

Sugar

Steel

Mining

Chemicals