Our experience in Winergy windturbine inspections

GBS Gearbox Services international is the fastest, full service, worldwide specialist in gearbox inspection and repair of Winergy windturbine gearboxes. We have executed many inspections on wind turbines with this type of gearboxes and therewith know where to look in more detail. Our inspected windfarms where all over Europe. We got those inspection orders by energy companies, insurance companies, windmill suppliers and independant service companies. Taking the latest innovations of our gearbox service experts, our goal is to get, often mission critical, gearboxes back into production at the shortest timespan possible. We have a winning track record in Winergy servicing! Having experience with a wide variaty of brands, we know the weakspots and strengths of any brand and can not only repair but often improve the reliability of any gearbox.

Our Technicians have experience on the Winergy PEAB PEAC PEAS and PZAB gearboxes

|

It is the task of the gear unit to step up the low speed of the rotor shaft via several gear

stages to the high speed of the output shaft driving the rotor of the generator via the coupling. The gear unit mainly comprises

four subassemblies: Castings (housing, planet carrier, torque reaction arms); geared parts

(gears, pinion shafts); rolling bearings, and

small parts. To step up the low rotor shaft speed to the required high speed level, different gear stages are combined in a wind turbine gear unit. The present standard is a combination of one planetary gear stage (low-speed gear stage) and two helical gear stages (high-speed gear stages) or two planetary gear stages and one helical gear stage. Winergy developed this concept of today's standard gear units and introduced it onto the market in 1989; and in the then following years it was adapted by the competitors. Winergy is market and quality leader both on the entire market for wind turbine gear units and in the fast growing multi-megawatt class. At present, our range features four gear unit types of different sizes as series products covering a power rating range from 600 to 5,000 kW. |

|

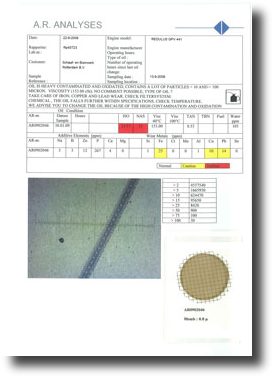

Our end-guarantee inspections

During the last few years our experts have performed many wind-energy gearbox inspections. All our inspections include an oil-analyses, visual inspections of

the bearings and gears, temperature measurements and vibration measurements. We have executed this type of work on many wind farms mostly in Europe, at the highest safety and quality level.

Our technicians have up-to-date training on safety and working at heights. Our inspection reports include the oil analyses, a schedule-drawing of the gearbox, pictures and data, and are all

finalized with clear conclusions and advice.

Our Machine Diagnostics Technicians

| Stefan van de Lavoir | Walter Bonnier | Dennis van Geemert | Arjan Visser | |||

|

|

|

|

|||

| See more | See more | See more | See more |

Our Machine Diagnostics Technicians are trained as follows

| Safety Certificate VCA |   |

|

| Windturbine towerclimbing training | ||

| Advanced training vibration analyses | ||

| Applied diagnostic training from Bently Nevada | ||

| Oil analyses training | ||

Our gearbox inspection reports

Our inspection equipment

So contact us now, for your End of Warranty support request and be assured you will get the fasest, most reliable Gearbox service experts available!