Home

©2008 Schaaf- en Boorwerk Rotterdam BV All rights reserved.

Gearbox Services

Our Bently Nevada ADRE system is one of the most commonly used and recognized diagnostic data acquisition systems available. The emphasis of the ADRE system is focussed towards Turbo Machinery, but as described below, other jobs have also been performed with great success. Our team of engineers has over 40 years of combined experienced and is well trained on the ADRE equipment.

The ADRE system is particularly well suited for:

- Turbo Machinery commissioning jobs

- Field balancing

- Troubleshooting, to identify:

- Stiffness and damping related problems

- Fluid induced instabilities

- Rubs

- Process related problems

- Thermal related problems

- Unidirectional preload related problems such as misalignment

A customer noticed a sudden increase of the shaft vibration level on their Bently Nevada vibration protection system. The customer contacted us to identify the root cause of the problem and if the problem could be solved without major down time.

What GBS Gearbox Services offered:

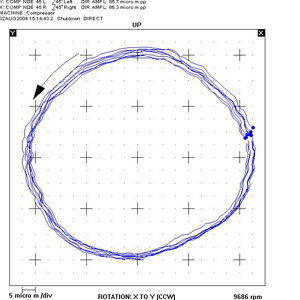

Our ADRE system was connected to the customers protection system for advanced diagnostic capabilities under different operational conditions. The recorded data had all the characteristics of unbalance. The vibration level was related to speed. The frequency was equal to the rotational frequency of the compressor and the orbit figures were circular on both ends of the rotor. It was decided not to balance the rotor in-situ due to the fact that the increase of vibration level happened suddenly, which suggests that something is stuck inside the rotor, broken of or shifted

Diagnostics Services on Gearboxes and General Rotating Equipment

Multichannel data acquisition system from Bently Nevada

Delaval barrel type Gas Compressor with high shaft vibrations - Example project No.1

During dismantling of the compressor it became clear that a piece of strainer had entered the compressor and got stuck within one of the impellers.

Luxury yacht with excessive hull vibrations - Example project No.2

A specific type of yacht had vibration problems which occured at a certain sailing speed. The cause of this vibration is currently under investigation by the ship builder. As a possible cause, the propeller shafts were pointed out. Excessive shaft vibration is thought to excite a hull resonance.

What GBS Gearbox Services offered:

By measuring the displacement of the propeller shaft, we answered the question whether the propeller shaft is causing the vibration problem and under which circumstances it occurs.

Commissioning / acceptance surveys - Example project No.3

Our engineers assisted many customers around the world during commissioning of their newly installed or overhauled installations.

What GBS Gearbox Services offered:

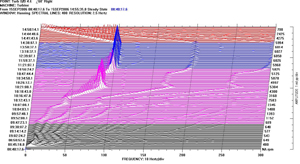

During commissioning we were able to verify if the recorded dynamic behaviour of the machine was conform international recognized standards, such as API or ISO. ADRE was used for data acquisition and is normally connected to the customers vibration protection system. Acceptance reports are made including all relevant machine baseline information. In other occasions the recorded data was used to discuss corrective actions. We also assisted customers with programming and optimizing their online condition monitoring systems.

Gas turbine balancing, GE Frame 5 (MS 5001) - Example project No.4

A customer was operating their compressor close to the vibration alarm setpoint. Our engineers were asked to analyze the problem and if possible reduce the vibration level.

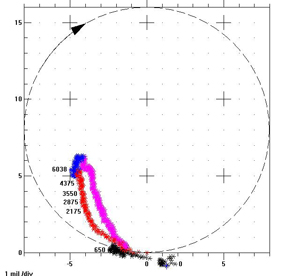

What GBS Gearbox Services offered:

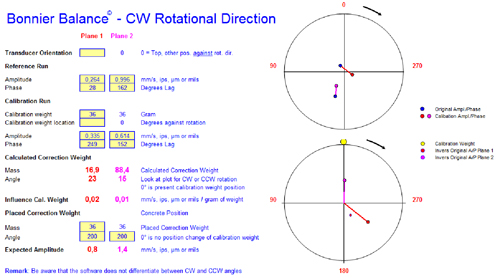

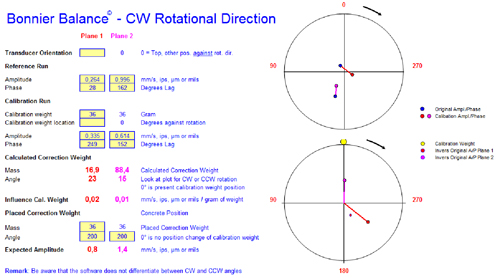

Transient vibration data was recorded with our ADRE system to identify the root cause of the elevated vibration levels. In this case unbalance caused by fouling on the impellers was identified as the root cause. After repeatability of the problem was confirmed and rotor washing did not show any influence it was decided to balance the machine in situ. In situ trim balancing is a very cost effective way to reduce elevated vibration level without taking the machine apart.

Reference list of balance jobs all executed with ADRE equipment:

-GE Frame 5 (MS 5001) gas turbines

-GE Frame 6B gas turbines

-GE Frame 9FA gas turbines

-GE LM 1600 power turbines

-GE LM 2500 gas turbines

-GE LM 6000 gas turbines

-Siemens V64 gas turbines

-Siemens Tornado power turbines

-GE Steam Turbines

-Solar barrel compressors

-Delaval (Siemens) barrel compressors

-Nuovo Pignone barrel compressors

-Elliott horizontal split line compressors

-Kawasaki centrifugal air compressor

-Praxair cryogenic expander

-Flow serve boiler feed water pump

-A large number of ventilators

GBS Gearbox Services international

brand of Schaaf- en Boorwerk Rotterdam B.V.