Global Activities

Our activities in the Netherlands

Our headquarters are located in The Netherlands and we serve a lot of clients in our own country. On this page a selection of gearbox projects done in The Netherlands are included. More information about the project can be viewed by clicking on the links listed below.

Inspection and repair on ZPMC gearbox

We advise:

- Taking a sample by means of pumps from the crankcase of the gearbox, shortly after turning the gearbox and perform an oil analysis again.

- Perform a visual inspection and vibration measurement annually.

We advise:

- Taking a sample by means of pumps from the crankcase of the gearbox, shortly after turning the gearbox and perform an oil analysis again.

- Perform a visual inspection and vibration measurement annually.

ZPMC

Inspection and repair on ZPMC gearbox

Recommendations:

- A oil analysis

- Provide the correct quantity and quality of oil with the gear unit

- Carry out a new vibration measurement after correcting the oil level or replacing the oil

- Measure the flank clearance of the 1st stage and carry out further inspection if the complaint continues

- Perform an annual vibration measurement and visual inspection.

Recommendations:

- A oil analysis

- Provide the correct quantity and quality of oil with the gear unit

- Carry out a new vibration measurement after correcting the oil level or replacing the oil

- Measure the flank clearance of the 1st stage and carry out further inspection if the complaint continues

- Perform an annual vibration measurement and visual inspection.

ZPMC

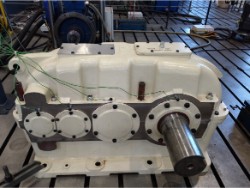

Inspection and repair on FLENDER KFO 630 gearbox

- Visually check the cabinet for cracks, where possible

- Visually checking the preservation internally and externally

- Checking the holes for damage and dimensions

- Checking the flatness (fit) of the division planes

Inside work:

- Checking condition of the toothing of all gear transmissions

- Checking the bearings for damage phenomena

- Checking bearing images and flank clearance of all gear transmissions

- Checking the shaft sizes for the bearings, oil seals, gears and couplings on dimensions and damage

- Checking the toothing for cracks by means of Magnaflux.

- Visually check the cabinet for cracks, where possible

- Visually checking the preservation internally and externally

- Checking the holes for damage and dimensions

- Checking the flatness (fit) of the division planes

Inside work:

- Checking condition of the toothing of all gear transmissions

- Checking the bearings for damage phenomena

- Checking bearing images and flank clearance of all gear transmissions

- Checking the shaft sizes for the bearings, oil seals, gears and couplings on dimensions and damage

- Checking the toothing for cracks by means of Magnaflux.

FLENDER KFO 630

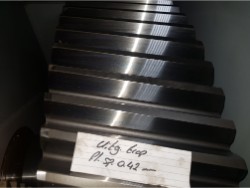

Inspection and repair on FLENDER SDN 400 gearbox

- Disassembly, cleaning and inspection

- Renew the bearings and seals

- Renew various small equipment

- Assembly and adjustment

- Test run with reporting

- Store the gear box externally in a 2-layer paint

Additional work following from inspection

- Dabbing the cupboard, dividing surfaces and bores

- Inside steps 1st stage, Incoming pinion shaft overhaul and Renew wheel teeth at least after grinding

- Retract 2nd stage, Pinion shaft and Gearwheel gear manually

- Inside 3rd stage, Pinion shaft and gear teeth Manually run after

- Machining the 3rd stage, pinion shaft and output shaft, cacking and retraining

- Renew the keys an

- Disassembly, cleaning and inspection

- Renew the bearings and seals

- Renew various small equipment

- Assembly and adjustment

- Test run with reporting

- Store the gear box externally in a 2-layer paint

Additional work following from inspection

- Dabbing the cupboard, dividing surfaces and bores

- Inside steps 1st stage, Incoming pinion shaft overhaul and Renew wheel teeth at least after grinding

- Retract 2nd stage, Pinion shaft and Gearwheel gear manually

- Inside 3rd stage, Pinion shaft and gear teeth Manually run after

- Machining the 3rd stage, pinion shaft and output shaft, cacking and retraining

- Renew the keys an

FLENDER SDN 400

Inspection and repair on BUSS G-160 gearbox

We advise:

- A comprehensive inspection by removing the upper division

- Let the I-care engineer set an automatic alarm which can warn in time if the amplitude of the tick increases

- Perform a vibration measurement and visual inspection every six months

We advise:

- A comprehensive inspection by removing the upper division

- Let the I-care engineer set an automatic alarm which can warn in time if the amplitude of the tick increases

- Perform a vibration measurement and visual inspection every six months

BUSS G-160

Inspection and repair on FLENDER NK NR SCH355/P/So gearbox

FLENDER NK NR SCH355/P/So

Inspection and repair on FLENDER KFO 630 gearbox

Recommendations:

- Replace the bearings in the bearing pot of the 1st stage

- Thoroughly clean the gearbox and the lubrication system to remove the metal particles from the system

- Carry out an inspection during the next stop to determine the progression of the bearing damage and the micropitting

- Adapt the lubrication system to provide the bearing pot with a higher volume flow of oil (or to consider the reverse mounting of the gearbox).

Recommendations:

- Replace the bearings in the bearing pot of the 1st stage

- Thoroughly clean the gearbox and the lubrication system to remove the metal particles from the system

- Carry out an inspection during the next stop to determine the progression of the bearing damage and the micropitting

- Adapt the lubrication system to provide the bearing pot with a higher volume flow of oil (or to consider the reverse mounting of the gearbox).

FLENDER KFO 630

Inspection and repair on FLENDER H2-SV-7B gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals, coupling and various small materials

- Revision activities and deliveries

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals, coupling and various small materials

- Revision activities and deliveries

- Assembly and adjustment

- Test run with reporting

FLENDER H2-SV-7B

Inspection and repair on OSTERMANN KNV2-280R gearbox

OSTERMANN KNV2-280R

Inspection and repair on RENK B34 / 76-M240 gearbox

Recommendations are:

- To continue vibration measurements according to the time schedule that was agreed upon with GBS

- To carry out an oil analysis yearly

- To carry out a visual inspection in case defect frequencies are observed or amplitudes increase significantly.

Recommendations are:

- To continue vibration measurements according to the time schedule that was agreed upon with GBS

- To carry out an oil analysis yearly

- To carry out a visual inspection in case defect frequencies are observed or amplitudes increase significantly.

RENK B34 / 76-M240

Inspection and repair on EKATO EKH-3V-84-670-VL gearbox

EKATO EKH-3V-84-670-VL

Inspection and repair on HEUBER 2-SF-900 gearbox

- Disassembly, cleaning and inspection

- Check interior (toothing) for cracks

- Renewing the bearings, SKF or FAG.

- The renewal of the seals, made by James Walker

- Renewing various small materials

- Assembly and adjustment

- Test run with reporting

- Preserve the gear box externally

- Disassembly, cleaning and inspection

- Check interior (toothing) for cracks

- Renewing the bearings, SKF or FAG.

- The renewal of the seals, made by James Walker

- Renewing various small materials

- Assembly and adjustment

- Test run with reporting

- Preserve the gear box externally

HEUBER 2-SF-900

Inspection and repair on FLENDER K3-HH-11-A gearbox

- Disassembly, cleaning and inspection

- Check interior (toothing) for cracks

- Renewing the bearings, SKF or FAG.

- The renewal of the seals, made by James Walker

- Renewing various small materials

- Assembly and adjustment

- Test run with reporting

- Preserve the gear box externally

- Disassembly, cleaning and inspection

- Check interior (toothing) for cracks

- Renewing the bearings, SKF or FAG.

- The renewal of the seals, made by James Walker

- Renewing various small materials

- Assembly and adjustment

- Test run with reporting

- Preserve the gear box externally

FLENDER K3-HH-11-A

Inspection and repair on EKATO EKH-3V-84-670-VL gearbox

Our recommendations are:

- Replacement of the bearings and seals

- Renew the internal preservation

- In the future, during storage, store the gearbox in a dry and warm environment and fill it with preservative oil.

Our recommendations are:

- Replacement of the bearings and seals

- Renew the internal preservation

- In the future, during storage, store the gearbox in a dry and warm environment and fill it with preservative oil.

EKATO EKH-3V-84-670-VL

Inspection and repair on KUMERA TD-3500K R E1 gearbox

KUMERA TD-3500K R E1

Inspection and repair on M.A.N. Katrijden gearbox

M.A.N. Katrijden

Inspection and repair on RENK Aws 315 So gearbox

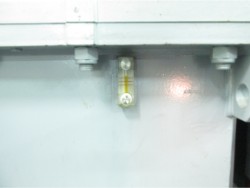

During the inspection, following observations were made:

- While using either the electric standby oil-pump or the mechanical oil-pump, lubrication oilpressure in pos. 43 is relatively low (0,4-0,8 [bar] respectively)

- The clutch control pressure in pos. 20 seems normal; circa 10,0-12,0 [bar] while both clutches are in disengaged (neutral) and 23,0-25,0 [bar] with either the forward or reverse clutch engaged.

- However, the clutch control pressure increases to 35,0 to 40,0 [bar] when both oil-pumps (standby and mechanical) are run simultaneously.

- The accumulating valve (pos. 30) was leaking oil, this was solved by replacing the o-rings inside the valve

During the inspection, following observations were made:

- While using either the electric standby oil-pump or the mechanical oil-pump, lubrication oilpressure in pos. 43 is relatively low (0,4-0,8 [bar] respectively)

- The clutch control pressure in pos. 20 seems normal; circa 10,0-12,0 [bar] while both clutches are in disengaged (neutral) and 23,0-25,0 [bar] with either the forward or reverse clutch engaged.

- However, the clutch control pressure increases to 35,0 to 40,0 [bar] when both oil-pumps (standby and mechanical) are run simultaneously.

- The accumulating valve (pos. 30) was leaking oil, this was solved by replacing the o-rings inside the valve

RENK Aws 315 So

Inspection and repair on PWH 2-SG-900 gearbox

PWH 2-SG-900

Inspection and repair on ASUG GVE 800x3,75-800x0,4 gearbox

Scope of work:

- Inspection of all shaft, gears and bearings

- Inspection and disassembly of remaining parts

- Replacement of all roller bearings

- Check of the axial clearance of all bearings

- Assembly of the gearbox on board the ship

- Assembly of the oil system

- Flushing of the gearbox

- Test run of the gearbox without

Scope of work:

- Inspection of all shaft, gears and bearings

- Inspection and disassembly of remaining parts

- Replacement of all roller bearings

- Check of the axial clearance of all bearings

- Assembly of the gearbox on board the ship

- Assembly of the oil system

- Flushing of the gearbox

- Test run of the gearbox without

ASUG GVE 800x3,75-800x0,4

Inspection and repair on WGW KSHK 1330 S/So gearbox

WGW KSHK 1330 S/So

Inspection and repair on FLENDER Sonder 195 gearbox

- Disassembly, cleaning and inspection

- Renew the bearings and seals

- Preserve the gear box externally

- Assembly and adjustment

- Test run with reporting

- Delivery of transport gearbox

- Apply oversized pin box cabinet (division)

- Renovate the first stage, the conical gear set

- Renovate 2nd stage, Pinion shaft and Sprocket

- Retract 3rd stage, Pinion shaft and Gear wheel manually

- Manually inspect other interior work

- renew 2 pieces of bronze cans for outgoing (hollow) axles

- Renew the labyrinth ring

- Fasteners and various small materials

- Turn the bearing covers at height when fitted

- Work pre

- Disassembly, cleaning and inspection

- Renew the bearings and seals

- Preserve the gear box externally

- Assembly and adjustment

- Test run with reporting

- Delivery of transport gearbox

- Apply oversized pin box cabinet (division)

- Renovate the first stage, the conical gear set

- Renovate 2nd stage, Pinion shaft and Sprocket

- Retract 3rd stage, Pinion shaft and Gear wheel manually

- Manually inspect other interior work

- renew 2 pieces of bronze cans for outgoing (hollow) axles

- Renew the labyrinth ring

- Fasteners and various small materials

- Turn the bearing covers at height when fitted

- Work pre

FLENDER Sonder 195