Global Activities

Our activities in Belgium

On this page you will find a selection of the projects we have done in Belgium. Since Belgium is only a few hours away from our headquarters in The Netherlands, we have done a lot of projects in this country. By clicking on one of the links below you can view the details of the project.

We performed an inspection and repair on a gearbox LOCKER-ROTEX 842 SS/SS.

We performed an inspection and repair on a gearbox Jahnel Kestermann ASVU-110-3HX-100.

We performed an inspection and revision on FLENDER gearbox KMP-200.

We performed an inspection and revision on FLENDER gearbox KBH P2SB-22.

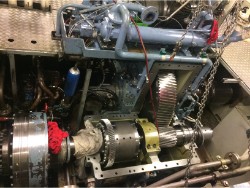

Inspection and repair on FLENDER SDN 450 gearbox

During the inspection, a few bolt holes of the aluminum oil cooler have been rotated. This was solved on the spot by providing all four bolt holes with Helicoils. The oil cooler was then tested by raising the water pressure again, no leakages were observed.

We advise:

- Continue the vibration measurements and visual inspections at the same interval

- If a change in vibration levels, or error frequencies is detected, perform a visual inspection again

- At a subsequent revision, install a filter element in the lubrication system of the Flender KLN 250

- Adjust the axial clearance of the flexible coupling correctly.

We advise:

- Continue the vibration measurements and visual inspections at the same interval

- If a change in vibration levels, or error frequencies is detected, perform a visual inspection again

- At a subsequent revision, install a filter element in the lubrication system of the Flender KLN 250

- Adjust the axial clearance of the flexible coupling correctly.

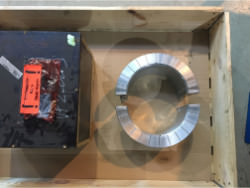

FLENDER SDN 450

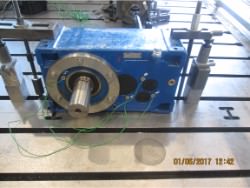

Inspection and repair on FLENDER SDN-250 gearbox

External:

- Visually check the gearbox for cracks, where possible.

- Visually checking the preservation internally and externally.

- Checking the holes for damage and dimensions.

- Checking the drillings for alignment deviations on the boring bench.

- Checking the flatness (fit) of the division planes.

Internal:

- Checking condition of the toothing of all gear transmissions.

- Checking the bearings for damage phenomena.

- Checking bearing images and flank clearance of all gear transmissions.

- Checking the shaft sizes for the bearings, oil seals, gears and couplings on dimensions and damage.

- Checking the axles for sway. - Chec

External:

- Visually check the gearbox for cracks, where possible.

- Visually checking the preservation internally and externally.

- Checking the holes for damage and dimensions.

- Checking the drillings for alignment deviations on the boring bench.

- Checking the flatness (fit) of the division planes.

Internal:

- Checking condition of the toothing of all gear transmissions.

- Checking the bearings for damage phenomena.

- Checking bearing images and flank clearance of all gear transmissions.

- Checking the shaft sizes for the bearings, oil seals, gears and couplings on dimensions and damage.

- Checking the axles for sway. - Chec

FLENDER SDN-250

Inspection and repair on KELLER AN725 gearbox

GBS international was invited to analyze and repair the damages in cooperated with the crew on board at Zeebrugge in Belgium.

GBS international was invited to analyze and repair the damages in cooperated with the crew on board at Zeebrugge in Belgium.

KELLER AN725

Inspection and repair on JAHNEL-KESTERMANN WD-A4S1520 gearbox

JAHNEL KESTERMANN WD-A4S1520

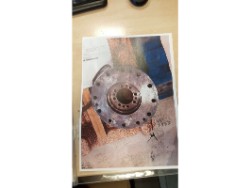

Inspection and repair on DESCH Planetaire gearbox

DESCH Planetaire

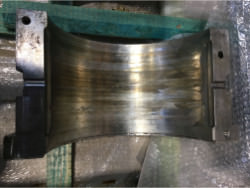

All white metal bearings and shafts are badly damaged.

The cause for this is; the lubrication between the shaft and the bearing was inadequate.

This could be due to;

- Too much water in the oil (a lot of corrosion has been observed)

- Incorrect start-up procedure during start-up, as a result of which there is an insufficient oil film between shaft and bearing during start-up

- A combination of the above

The cause for this is; the lubrication between the shaft and the bearing was inadequate.

This could be due to;

- Too much water in the oil (a lot of corrosion has been observed)

- Incorrect start-up procedure during start-up, as a result of which there is an insufficient oil film between shaft and bearing during start-up

- A combination of the above

DAVID BROWN HSN-250-SRG

We performed an inspection and repair on a EKATO gearbox.

EKATO UNKNOWN

We performed an inspection and repair on a gearbox Jahnel Kestermann ASVU-110-3HX-100.

JAHNEL KESTERMANN ASVU-110-3HX-100

We performed an inspection and repair on a gearbox MOTO MECHANICA MG1800.

MOTO MECHANICA MG1800

We performed an inspection and revision on gearbox of ITAYA GR CH204.

ITAYA GR CH204

We performed an inspection and revision on gearbox Knödler FZ600.2-280.

KNODLER FZ600.2-280

We performed an inspection and repair on a gearbox Jahnel Kestermann GD-A1S710.

JAHNEL KESTERMANN GD-A1S710

We performed an inspection and revision on FLENDER gearbox .

FLENDER UNKNOWN

We performed an inspection and repair on a gearbox VALMET S1G-280ARIT1F GEARBOX.

VALMET S1G-280ARIT1F

We performed an inspection and repair on a gearbox Lightnin 88S 75.

LIGHTNIN 88S 75

We performed an inspection and repair on a gearbox Rossi MRC21280-UO2A-200.

ROSSI MRC21280-UO2A-200

We performed an inspection and revision on FLENDER gearbox GP1 320.

FLENDER GP1 320

We performed an inspection and repair on a gearbox Jahnel Kestermann GD-A1S710.

JAHNEL KESTERMANN GD-A1S710

We performed repair on a gearbox Kissling VDRU-550 LEM.

KISSLING VDRU-550 LEM

We performed an inspection and repair on a gearbox LOCKER-ROTEX 842 SS/SS.

LOCKER-ROTEX 842 SS/SS

We performed an inspection and repair on a gearbox Jahnel Kestermann ASVU-110-3HX-100.

KESTERMAN ASVU-110-3HX-100

We performed an inspection and repair on a KELLER gearbox

KELLER S 2 S III H500

We performed an inspection and revision on FLENDER gearbox KMP-200.

FLENDER KMP-200

We performed an inspection and revision on FLENDER gearbox KBH P2SB-22.

FLENDER P2SB-22 (planetair)