Our Gearbox Expertises

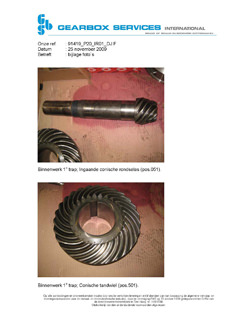

Machine Diagnostics

Our team of inspection engineers is one of the most experienced and well educated in Western Europe.We have done many inspections and Failure root cause analyses in many industrial, maritime and wind industries.

Further our department has knowledge on

- Condition based maintenance

- Equipment health management

- Torque and power measurements

Onsite gearbox inspection, repair, alignment and commissioning

Our service engineers have besides their tremendous commitment and flexibility, also a great knowledge of gearboxes in their specific environment. Often the environment is the basis for earlier failure. In addition to onsite inspections and assembly, we can execute the following:-Field trim balancing

-Geometrical measurements

-Thermal growth studies

-Torque and power measurements

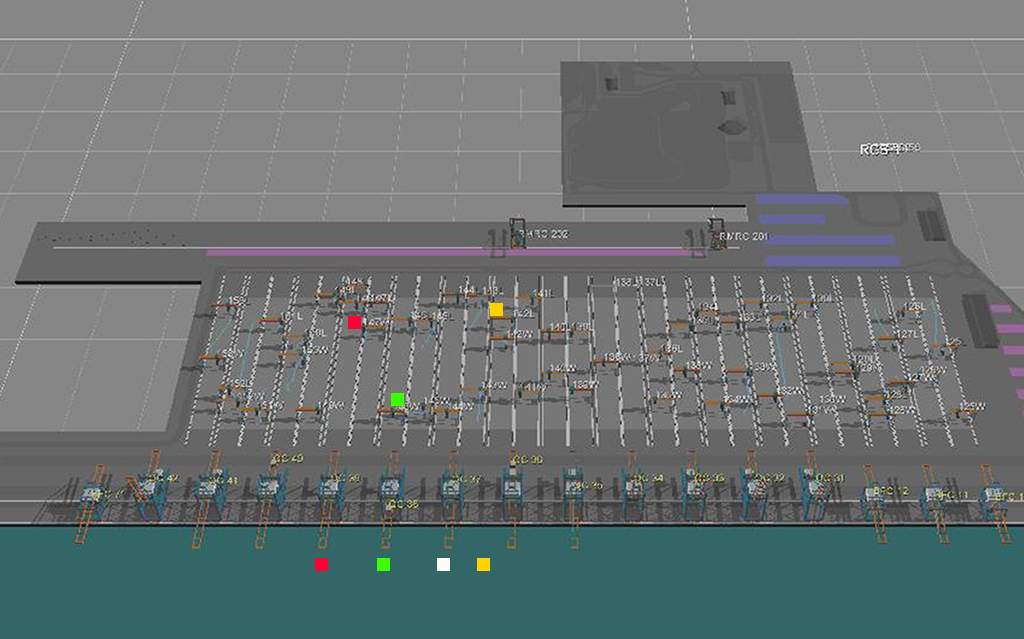

Onsite gear measurement

We have an portable 6 axes gear measurement tool. With this measurement tool we can check and measure the profiles on-site of unknown gears.For our customers, this has the advantage that we can measure components in the gearbox. Vulnerable parts need no longer to be transported with all the risks. Gearboxes should be opened just for an short lead-time. Existing heavy gears that should be replaced, doesn't need to be transported with high costs.

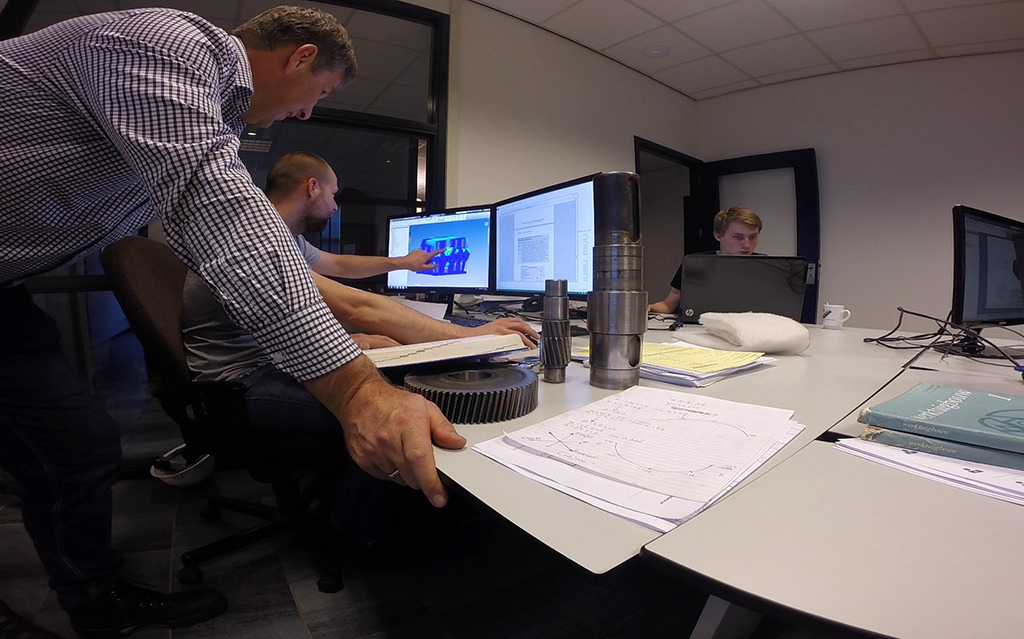

Engineering

Our engineering department focuses on all issues of gearboxes.A broad practical experience combined with modern equipment makes us distinctive.

Our department consists of employees with an average of 15 years experience in gearboxes of many brands for many applications, such as wind, the dredging industry, shipping, energy production and container and bulk handling.

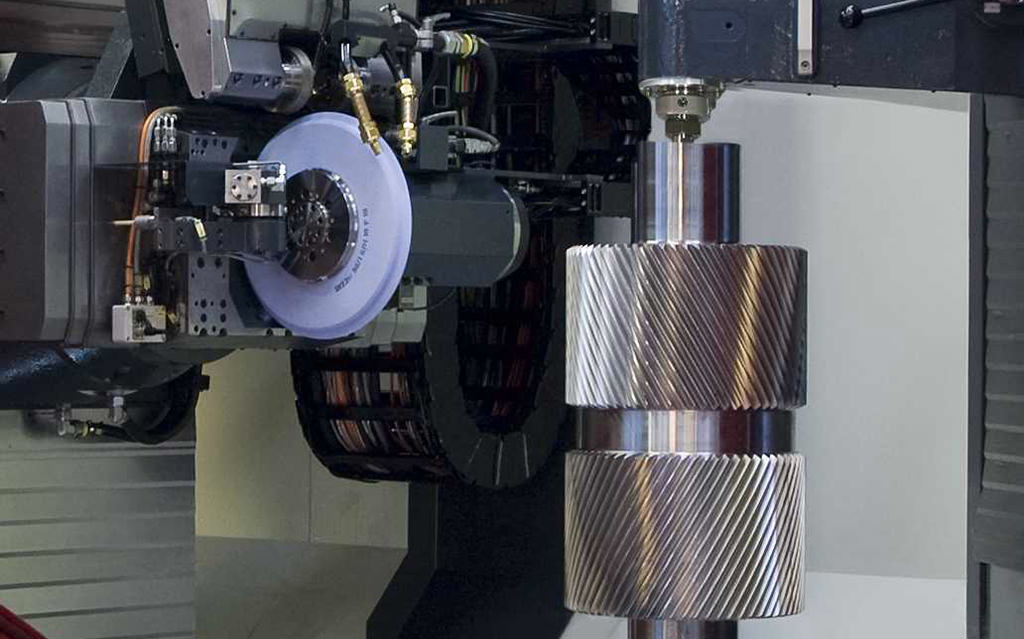

Machining of gears, gearbox housings and other related parts

Our company has an machining department with about 35 employees. From 2009, we have made significant investments in new machinery, including a Niles for grinding the gears. Furthermore, we have started the production of gears on 5-axis milling machines. Our production portfolio in terms of gearboxes looks therefore as follows:-housings

-white-metal bearings

-gears

-shafts

Inspection and repair of gearboxes in our workshop

From 2009 we have trained a group of 20 engineers, which work as well on site as our workshop. Our main tasks are:-complete inspection,

-troubleshooting

-reporting and

assembly.

In 2016 we will expand our company with a specially equipped assembly hall.

Test run of gearboxes all our gearboxes

All our gearboxes are subjected to a test to our test stand.GBS Gearbox Services develops a triple-500 kW-Oil-Purity test facility, which will be ready mid 2016.

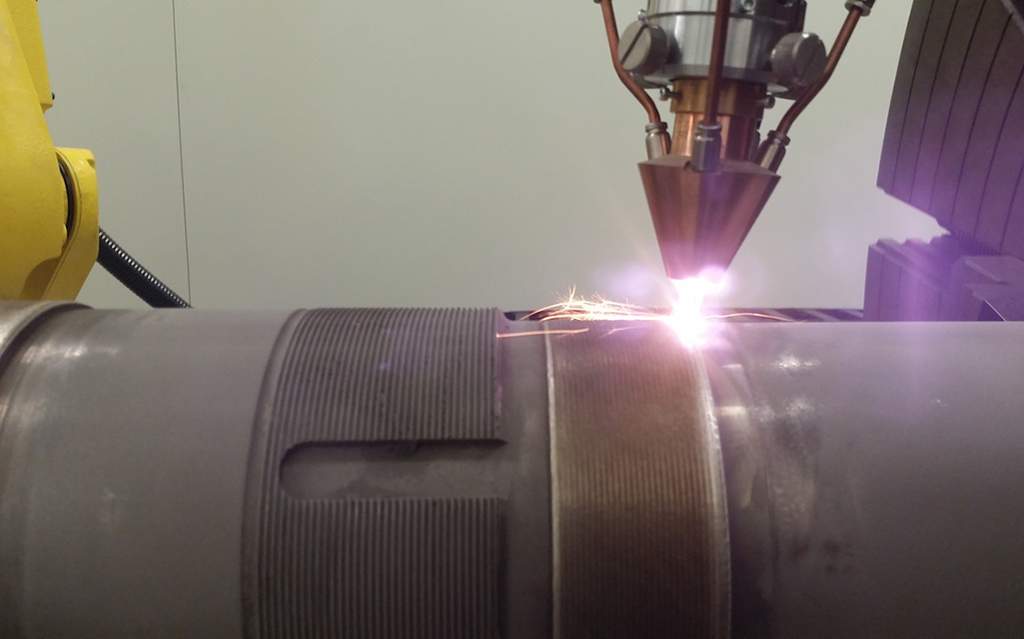

Laser Cladding

In the cabin, we can roughly handle big size of objects:

Zero leakage program

We are willing to determine de common cause of failure and to find an solution to reduce the failure mode of oil-gaskets and -seals.We will do research to find the root cause of different leakages and provide professional advice to our customers.