Our activities in Bulk & Container Handling

Overview of our gearbox inspection and repair projects in the Bulk & Container Handling Industry

The Bulk & Container Handling Industry is an important industry for us. Since we are located in The Netherlands near Rotterdam, we do a lot of project for the port of Rotterdam. On this page will find a collection of projects we have done in this industry. By clicking on one of the links below, you can see the details of the project.

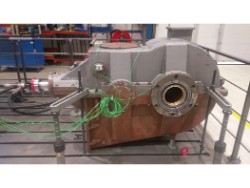

Inspection and repair on WGW KSHK 1330 S/So S/So gearbox

- Cleaning, inspection and assembly

- Renewing bearings, seals and various small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport gearbox back to client

- Cleaning, inspection and assembly

- Renewing bearings, seals and various small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport gearbox back to client

WGW KSHK 1330 S/So

Inspection and repair on WGW KSHK 1330 S/So gearbox

- Cleaning, inspection and assembly of the gearbox

- Renewing bearings, seals and various other small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport of the gearbox back to the customer

- Cleaning, inspection and assembly of the gearbox

- Renewing bearings, seals and various other small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport of the gearbox back to the customer

WGW KSHK 1330 S/So

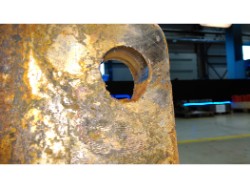

Inspection and repair on WGW AA-SCZ-600/2/S gearbox

We recommended:

- In the short term, carry out an extensive inspection of the gearbox to determine the origin of the grit (by removing the top cover)

- Regardless of the result of the extensive inspection, the gearbox must be cleaned

- To refresh or filter the oil for reuse in order to remove any metal particles

- Perform a visual inspection and oil analysis annually.

We recommended:

- In the short term, carry out an extensive inspection of the gearbox to determine the origin of the grit (by removing the top cover)

- Regardless of the result of the extensive inspection, the gearbox must be cleaned

- To refresh or filter the oil for reuse in order to remove any metal particles

- Perform a visual inspection and oil analysis annually.

WGW AA-SCZ-600/2/S

Inspection and repair on WGW KSHK 1330 S/So gearbox

WGW KSHK 1330 S/So

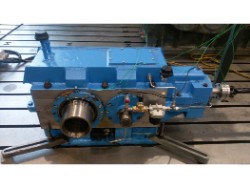

Inspection and repair on FLENDER NK NR SCH355/P/So gearbox

FLENDER NK NR SCH355/P/So

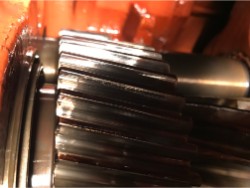

Inspection and repair on WGW KSHK 1330 S/So gearbox

Scope of work:

- Cleaning, inspection and assembly

- Renewing bearings, seals and various small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport

Additional work following from inspection:

- Applying oversized dowel pins.

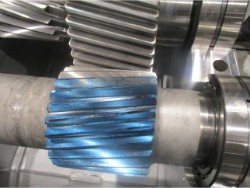

- The mechanical minimum clean-up of distance rings and spacer for renewal of the conical pinion shaft

- Inbound conical pinion shaft for pre-machining, capping and naming the seal

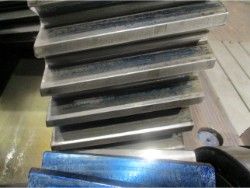

- Manually check inside gear teeth

- Offset hollow shaft (pos.9) in connection with seal on both sides, material 42CrMo4

- Renov

Scope of work:

- Cleaning, inspection and assembly

- Renewing bearings, seals and various small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport

Additional work following from inspection:

- Applying oversized dowel pins.

- The mechanical minimum clean-up of distance rings and spacer for renewal of the conical pinion shaft

- Inbound conical pinion shaft for pre-machining, capping and naming the seal

- Manually check inside gear teeth

- Offset hollow shaft (pos.9) in connection with seal on both sides, material 42CrMo4

- Renov

WGW KSHK 1330 S/So

Inspection and repair on WGW KSHK 1330 S/So gearbox

Scope of work:

- Cleaning, inspection and assembly

- Renewing bearings, seals and various small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport (delivery)

Scope of work:

- Cleaning, inspection and assembly

- Renewing bearings, seals and various small materials

- Test run with test run protocol

- Update the gearbox internally and remove, sand, degrease and conserve externally

- Transport (delivery)

WGW KSHK 1330 S/So

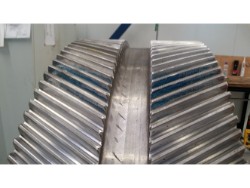

Inspection and repair on FLENDER SOND-175 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

FLENDER SOND-175

Inspection and repair on HANSEN DM-933-ATS gearbox

HANSEN DM-933-ATS

Inspection and repair on ZPMC gearbox

GBS has been instructed to find the cause of abnormal vibrations and strange noises from gearboxes. The complaints are described as follows:

"Gearbox gives great vibration which is easily felt in the floor" "2nd cat hoist has a separate sound, possibly with input shaft or first stage"

We recommended:

- Ensure that the gear units are filled with the correct amount of oil, for example by fitting new oil level glasses

- To be able to detect the development of a damage on time every three months to perform a vibration measurement

- Carry out a yearly visual inspection (and increase the vibration levels or detection of error frequencies).

GBS has been instructed to find the cause of abnormal vibrations and strange noises from gearboxes. The complaints are described as follows:

"Gearbox gives great vibration which is easily felt in the floor" "2nd cat hoist has a separate sound, possibly with input shaft or first stage"

We recommended:

- Ensure that the gear units are filled with the correct amount of oil, for example by fitting new oil level glasses

- To be able to detect the development of a damage on time every three months to perform a vibration measurement

- Carry out a yearly visual inspection (and increase the vibration levels or detection of error frequencies).

ZPMC UNKNOWN

Inspection and repair on FLENDER KBH 400/S/So gearbox

FLENDER KBH 400/S/So

Inspection and repair on WGW KS 5,75 /S/So gearbox

Scope of work:

- Cleaning, inspection and assembly

- Repair bearings, seals and various small materials

- Test run with test run protocol

- Dispose of gearbox, internally and externally, sand, degrease and preserve

- Transport (delivery)

Scope of work:

- Cleaning, inspection and assembly

- Repair bearings, seals and various small materials

- Test run with test run protocol

- Dispose of gearbox, internally and externally, sand, degrease and preserve

- Transport (delivery)

WGW KS 5,75 /S/So

Inspection and repair on FLENDER B3SH-05-A gearbox

FLENDER B3SH-05-A

Inspection and repair on FLENDER NK NR SCH355/P/So gearbox

FLENDER NK NR SCH355/P/So

Inspection and repair on BIERENS DW15/26-Spec gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

BIERENS DW15/26-Spec

Inspection and repair on WGW AA-SCZ-600/2/S gearbox

Our recommendations are:

- To keep following the vibration levels of the bearings

- To perform a visual inspection once again in case of an increase or change of vibration levels

- Give extra attention to the cause of the oil leak during the next batch of the division.

Our recommendations are:

- To keep following the vibration levels of the bearings

- To perform a visual inspection once again in case of an increase or change of vibration levels

- Give extra attention to the cause of the oil leak during the next batch of the division.

WGW AA-SCZ-600/2/S

Inspection and repair on THYSSENKRUPP KSZg 355 Pu gearbox

THYSSENKRUPP KSZg 355 Pu

Inspection and repair on KUMERA RD-4630-L-E1 gearbox

KUMERA RD-4630-L-E1

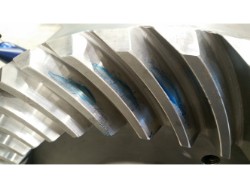

Inspection and repair on DEMAG 200 ZW/KR gearbox

Scope of work:

- Disassembly, cleaning and inspection of the gearbox

- Renewing all bearings and seals.

- Mounting and adjusting the gearbox.

- Test run of the gearbox.

- The internal and external preservation of the gearbox.

- Transport, delivery of the gearbox.

- Renew pin axis 2nd stage oversize

- 2nd stage gear, toothing on both flanks at least regrinding.

- Renew the outgoing spline shaft

- The renewal of the incoming wear bush, tread hardened / Stelitte.

- Renewal of the outgoing wear bush, tread hardened / Stelitte.

- Renewing the oil dipstick

- Disassembly of newly supplied Malmedie coupling and fill with

Scope of work:

- Disassembly, cleaning and inspection of the gearbox

- Renewing all bearings and seals.

- Mounting and adjusting the gearbox.

- Test run of the gearbox.

- The internal and external preservation of the gearbox.

- Transport, delivery of the gearbox.

- Renew pin axis 2nd stage oversize

- 2nd stage gear, toothing on both flanks at least regrinding.

- Renew the outgoing spline shaft

- The renewal of the incoming wear bush, tread hardened / Stelitte.

- Renewal of the outgoing wear bush, tread hardened / Stelitte.

- Renewing the oil dipstick

- Disassembly of newly supplied Malmedie coupling and fill with

DEMAG 200 ZW/KR

Inspection and repair on BIERENS K2-A3-50 gearbox

- Renewal of the bearings and (shaft) seals

- The renewal of various small materials such as gaskets, fasteners, etc.

- Reassembly of the gearbox.

- Checking and recording the bearing images and flank clearance in the inspection report.

- Checking and recording the axial bearing clearances in the inspection report

- Prepare the test stand, set up the gearbox, fill it with oil and test it for 4 hours without load

- Renewal of the bearings and (shaft) seals

- The renewal of various small materials such as gaskets, fasteners, etc.

- Reassembly of the gearbox.

- Checking and recording the bearing images and flank clearance in the inspection report.

- Checking and recording the axial bearing clearances in the inspection report

- Prepare the test stand, set up the gearbox, fill it with oil and test it for 4 hours without load

BIERENS K2-A3-50

Inspection and repair on ZPMC NFH1610.28.C3B-00 gearbox

ZPMC FH1610.28.C3B-00