Our activities in the Dredging Industry

Presentation of our Dredging projects

Here you will find a selection of the gearbox related projects we have done in the Dredging market for clients all over the world. If you want more information about a project, you can click the link to view all the details.

Inspection and repair on FLENDER CUHW250 gearbox

- General disassembly and cleaning of all parts

- Inspect and report

- Go through the inspection report together during the work

- Assembly and testing

- General disassembly and cleaning of all parts

- Inspect and report

- Go through the inspection report together during the work

- Assembly and testing

FLENDER CUHW250

Inspection and repair on FLENDER CUHW250 gearbox

- Disassembly / assembly / test run gearbox

- Work preparation of project manager

- Delivery of new bearings and seals for input shaft

- Processing of input shaft (INA ring + spraying ceramic)

- Regrinding bore of belt pulley according to instructions

- Disassembly / assembly / test run gearbox

- Work preparation of project manager

- Delivery of new bearings and seals for input shaft

- Processing of input shaft (INA ring + spraying ceramic)

- Regrinding bore of belt pulley according to instructions

FLENDER CUHW250

Inspection and repair on HANSEN EH854A-205 gearbox

This report shows the results of the visual inspection and vibration analysis on the Ghent Tower Automotive wind turbine. The customer has instructed GBS to visually record the condition of the gearbox. In addition, the data from the online SKF vibration monitoring system will be compared with data recorded on-site.

This report shows the results of the visual inspection and vibration analysis on the Ghent Tower Automotive wind turbine. The customer has instructed GBS to visually record the condition of the gearbox. In addition, the data from the online SKF vibration monitoring system will be compared with data recorded on-site.

HANSEN EH854A-205

Inspection and repair on KISSLING TR-680 gearbox

We advise:

- To perform a new vibration measurement after the assembly of the new outgoing spline axles (this summer) and then annually

- Perform a visual inspection and oil analysis annually.

We advise:

- To perform a new vibration measurement after the assembly of the new outgoing spline axles (this summer) and then annually

- Perform a visual inspection and oil analysis annually.

KISSLING TR-680

Inspection and repair on ASUG GVE 800x3,75-800x0,4 gearbox

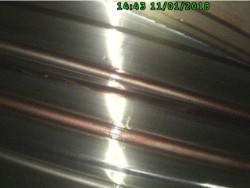

This page presents the overhaul of the propulsion gearbox’ PTO shaft, on board a ship. GBS was invited to perform the overhaul, following the initial inspection by GBS. The overhaul of the PTO shaft as described in this report, was carried out successfully. Bearings were replace and axial clearance re-adjusted. A test-run was finally carried out, showing no abnormalities in vibration, sound and temperatures.

The repair of the gearbox should however be considered as a temporary solution. As of a consequence of the diagnosed bearing damage, both bearing pockets showed severe (old) rotation marks.

In order to guarantee proper operation of the gearbox, it is re

This page presents the overhaul of the propulsion gearbox’ PTO shaft, on board a ship. GBS was invited to perform the overhaul, following the initial inspection by GBS. The overhaul of the PTO shaft as described in this report, was carried out successfully. Bearings were replace and axial clearance re-adjusted. A test-run was finally carried out, showing no abnormalities in vibration, sound and temperatures.

The repair of the gearbox should however be considered as a temporary solution. As of a consequence of the diagnosed bearing damage, both bearing pockets showed severe (old) rotation marks.

In order to guarantee proper operation of the gearbox, it is re

ASUG GVE 800x3,75-800x0,4

Inspection and repair on BUSS G-160 gearbox

Recommendations

- Determine lubricating oil pressure at connection 12 on the gearbox

- Determine the exact lubricating oil quantity (l / min) for the relevant plain bearing

- Have the oil sample analyzed (for the determination of any wear particles).

It is also advisable to check the flow at the current lubrication oil supply with the current spare gearbox.

There is no further control on location, which results in the reduction of the flow. If the exact flow to this bearing is known, it must be decided whether this is sufficient for the proper functioning of the installation.

Recommendations

- Determine lubricating oil pressure at connection 12 on the gearbox

- Determine the exact lubricating oil quantity (l / min) for the relevant plain bearing

- Have the oil sample analyzed (for the determination of any wear particles).

It is also advisable to check the flow at the current lubrication oil supply with the current spare gearbox.

There is no further control on location, which results in the reduction of the flow. If the exact flow to this bearing is known, it must be decided whether this is sufficient for the proper functioning of the installation.

BUSS G-160

Inspection and repair on LOHMANN+STOLTERFOHT GAA560WN 1500W gearbox

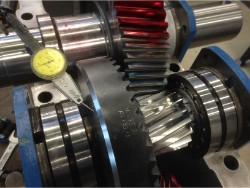

Conclusion of the overhaul from this gearbox are that the bearings were on his running hours, minor corrosion and little spots on the gears from running hours. The spots and marks that you see on the gears are from still standing, because of the vibration from the ship comes in the still standing gears on each other.

probably would input shaft bearings not make his running hours, that is because of the wrong storage of the spiroflex elements, with a wrong storage the Spiroflex isn’t balanced any more so you get vibration on your coupling, shaft and bearings.

Recommendations

For the right storage of the spiroflex elements, GBS recommends to hor

Conclusion of the overhaul from this gearbox are that the bearings were on his running hours, minor corrosion and little spots on the gears from running hours. The spots and marks that you see on the gears are from still standing, because of the vibration from the ship comes in the still standing gears on each other.

probably would input shaft bearings not make his running hours, that is because of the wrong storage of the spiroflex elements, with a wrong storage the Spiroflex isn’t balanced any more so you get vibration on your coupling, shaft and bearings.

Recommendations

For the right storage of the spiroflex elements, GBS recommends to hor

LOHMANN STOLTERFOHT GAA560WN 1500W

Inspection and repair on ZF ZFW43100 NR gearbox

The state of the gearbox can be considered as good, only minor running marks were observed on gears and bearings. Furthermore, the gearbox externals and engine room were very clean at the time of the inspection.

Since no drawings of the gearbox were available it was not possible to determine all bearing positions. It can be expected that a combination of radial and axial bearings is present on some shafts, however these where not accessible through the bearing in front. If the thrust bearing is severely damaged it could transfer damage to the next bearing on the shaft by means of indentation of debris, no such damage has been observed.

Another way to detect bearing da

The state of the gearbox can be considered as good, only minor running marks were observed on gears and bearings. Furthermore, the gearbox externals and engine room were very clean at the time of the inspection.

Since no drawings of the gearbox were available it was not possible to determine all bearing positions. It can be expected that a combination of radial and axial bearings is present on some shafts, however these where not accessible through the bearing in front. If the thrust bearing is severely damaged it could transfer damage to the next bearing on the shaft by means of indentation of debris, no such damage has been observed.

Another way to detect bearing da

ZF ZFW43100 NR

Inspection and repair on HANGZOU ADVANCE GEARBOX GWC 6066 gearbox

Scope of work:

- Visual inspection propulsion gearbox, Hangzhou Advance GWC 6066

Small leakages were observed around the gearbox oil pipes and covers.

Micro pitting is observed on the working flank of the pinion gear of the intermediate shaft ahead and working flank on the output shaft gearwheel of the output shaft.

Small steel particles were observed in the filter elements.

The bearings that were visible by eye show running marks. (the pictures taken with our camera were not detailed enough to add in the report) (endoscope was not available during inspection)

Scope of work:

- Visual inspection propulsion gearbox, Hangzhou Advance GWC 6066

Small leakages were observed around the gearbox oil pipes and covers.

Micro pitting is observed on the working flank of the pinion gear of the intermediate shaft ahead and working flank on the output shaft gearwheel of the output shaft.

Small steel particles were observed in the filter elements.

The bearings that were visible by eye show running marks. (the pictures taken with our camera were not detailed enough to add in the report) (endoscope was not available during inspection)

HANGZOU ADVANCE GWC 6066

Inspection and repair on ZOLLERN ZHP 4.25 gearbox

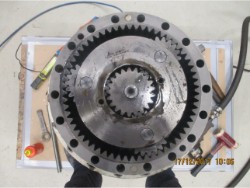

This page provides an overview of the inspection a ZOLLERN planetary winch gearbox.

The gearbox was sent to the GBS International workshop to carry out the inspection. All findings are listed here.

The working parts of the gearbox are in good condition, gears and shafts can be re-used, as well as the planetary gear bearings. Other bearings should be replaced.

This page provides an overview of the inspection a ZOLLERN planetary winch gearbox.

The gearbox was sent to the GBS International workshop to carry out the inspection. All findings are listed here.

The working parts of the gearbox are in good condition, gears and shafts can be re-used, as well as the planetary gear bearings. Other bearings should be replaced.

ZOLLERN ZHP 4.25

Inspection and repair on JAHNEL-KESTERMANN PGVC-630-435 gearbox

Scoop of work:

• Inspection Propulsion gearbox, Jahnel Kestermann, PGVC-630-435

Bearing pos. 1 of the input shaft, shows a gray dull appearance. No further damages were observed. However no information about the running hours of the gearbox were available.

The main engine running hours are exceeding the recommended gearbox running hours.

If the gearbox hasn’t been overhauled in the past, GBS recommend to replace the bearings during an overhaul. This to avoid an un planned, destruction repair. Please be aware no indications of significant wear is observed, however the condition of the expended bearing lifespan can change rapidly. <

Scoop of work:

• Inspection Propulsion gearbox, Jahnel Kestermann, PGVC-630-435

Bearing pos. 1 of the input shaft, shows a gray dull appearance. No further damages were observed. However no information about the running hours of the gearbox were available.

The main engine running hours are exceeding the recommended gearbox running hours.

If the gearbox hasn’t been overhauled in the past, GBS recommend to replace the bearings during an overhaul. This to avoid an un planned, destruction repair. Please be aware no indications of significant wear is observed, however the condition of the expended bearing lifespan can change rapidly. <

JAHNEL KESTERMANN PGVC-630-435

Inspection and repair on SANTASALO 4L92K gearbox

Scope of work:

- Disassembly and cleaning all parts

- Visual inspection and report

- New Bearings and shaft-seals

- Renewal of various small material

- Assembly and adjusting

- Test-run with report

- Externally de-greasing and painting of the gearbox

Scope of work:

- Disassembly and cleaning all parts

- Visual inspection and report

- New Bearings and shaft-seals

- Renewal of various small material

- Assembly and adjusting

- Test-run with report

- Externally de-greasing and painting of the gearbox

SANTASALO 4L92K

Inspection and repair on HANGZOU ADVANCE GEARBOX GWC 6066 gearbox

Scope of work:

- Visual inspection propulsion gearbox, Hangzhou Advance GWC 6066

Small leakages were observed around the gearbox oil pipes and covers.

Micro pitting is observed on the working flank of the pinion gear of the intermediate shaft ahead and working flank on the output shaft gearwheel of the output shaft.

Small steel particles were observed in the filter elements, most of these particles were brass material. This can be caused by wear on the clutch plates, or from the bearings with brass cages.

The bearings that were visible by eye show running marks. (the pictures taken with our camera were not detailed en

Scope of work:

- Visual inspection propulsion gearbox, Hangzhou Advance GWC 6066

Small leakages were observed around the gearbox oil pipes and covers.

Micro pitting is observed on the working flank of the pinion gear of the intermediate shaft ahead and working flank on the output shaft gearwheel of the output shaft.

Small steel particles were observed in the filter elements, most of these particles were brass material. This can be caused by wear on the clutch plates, or from the bearings with brass cages.

The bearings that were visible by eye show running marks. (the pictures taken with our camera were not detailed en

HANGZOU ADVANCE GWC 6066

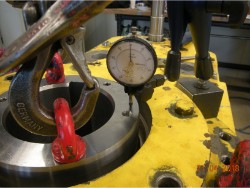

Inspection and repair on FLENDER gearbox

Scope of work:

- Disassembly / assembly / test run / painting

- Work preparation / project management

- Engineering

- Supply of teeth parts + cabinet Flender

- Deliver and edit Flender link

- Supply of bearings

- Delivering various small materials

- Delivery of material 18CrNiMo7.6

- Measuring existing cupboard

- Clocks of existing output shaft

- Create steel filling ring

- Routing out bolt from lantern piece

- Adjusting the mounting ring lantern piece

Scope of work:

- Disassembly / assembly / test run / painting

- Work preparation / project management

- Engineering

- Supply of teeth parts + cabinet Flender

- Deliver and edit Flender link

- Supply of bearings

- Delivering various small materials

- Delivery of material 18CrNiMo7.6

- Measuring existing cupboard

- Clocks of existing output shaft

- Create steel filling ring

- Routing out bolt from lantern piece

- Adjusting the mounting ring lantern piece

FLENDER

Inspection and repair on LOHMANN-STOLTERFOHT GJZ 1715 gearbox

The output shaft (assembly) was overhauled in the GBS International workshop, prior to sustaining damage during transport to the vessel. Upon discovering the damage, the client returned the shaft to GBS, to assess and repair the damage.

The output shaft (assembly) was overhauled in the GBS International workshop, prior to sustaining damage during transport to the vessel. Upon discovering the damage, the client returned the shaft to GBS, to assess and repair the damage.

LOHMANN STOLTERFOHT GJZ 1715

Inspection and repair on HANGZOU ADVANCE GEARBOX GWC 6066 gearbox

Scoop of work:

- Inpection Propulsion gearbox, Hangzhou Advance GWC 6066

Micro pitting is found on the working flank of the pinion gear of the intermediate shaft AHEAD and working flank of the Bull gear of the output shaft.

Micro pitting is a phenomenon that can be found on (hardened) gears. Multiple factors can affect the development of micro pitting, most important factors are surface roughness, lubrication or an incorrect gear mesh. The damage shows itself by a matted grey colour of the teeth. This as outcome of surface fatigue. The development of the micro pitting can be stabilized or progressive. A progressive development can eventual

Scoop of work:

- Inpection Propulsion gearbox, Hangzhou Advance GWC 6066

Micro pitting is found on the working flank of the pinion gear of the intermediate shaft AHEAD and working flank of the Bull gear of the output shaft.

Micro pitting is a phenomenon that can be found on (hardened) gears. Multiple factors can affect the development of micro pitting, most important factors are surface roughness, lubrication or an incorrect gear mesh. The damage shows itself by a matted grey colour of the teeth. This as outcome of surface fatigue. The development of the micro pitting can be stabilized or progressive. A progressive development can eventual

HANGZOU ADVANCE GWC 6066

Inspection and repair on TGW KBN-200 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Overhaul of the gearbox

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Overhaul of the gearbox

- Assembly and adjustment

- Test run with reporting

TGW KBN-200

Inspection and repair on FLENDER SDOS 280 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

- Transport (collection and delivery)

Other activities:

- Renewing the oil pump

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inside work 1st stage; Replace the pinion shaft, turn the gear and retighten manually

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

- Transport (collection and delivery)

Other activities:

- Renewing the oil pump

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inside work 1st stage; Replace the pinion shaft, turn the gear and retighten manually

FLENDER SDOS 280

Inspection and repair on FLENDER SDOS 360 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

- Transport (collection and delivery)

Other activities:

- Renewing the oil pump

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inside work 1st stage; Replace the pinion shaft, turn the gear and retighten manually

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

- Transport (collection and delivery)

Other activities:

- Renewing the oil pump

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inside work 1st stage; Replace the pinion shaft, turn the gear and retighten manually

FLENDER SDOS 360

Inspection and repair on BRINKMANN PL40SSA gearbox

BRINKMANN PL40SSA

Inspection and repair on LIEBHERR gearbox

LIEBHERR UNKNOWN

Inspection and repair on FLENDER GRAFFENSTADE AA 51 DA gearbox

FLENDER GRAFFENSTADEN AA 51 DA