Our activities in the Dredging Industry

Presentation of our Dredging projects

Here you will find a selection of the gearbox related projects we have done in the Dredging market for clients all over the world. If you want more information about a project, you can click the link to view all the details.

Inspection and repair on FLENDER KFO 630 gearbox

Recommendations:

- Replace the bearings in the bearing pot of the 1st stage

- Thoroughly clean the gearbox and the lubrication system to remove the metal particles from the system

- Carry out an inspection during the next stop to determine the progression of the bearing damage and the micropitting

- Adapt the lubrication system to provide the bearing pot with a higher volume flow of oil (or to consider the reverse mounting of the gearbox).

Recommendations:

- Replace the bearings in the bearing pot of the 1st stage

- Thoroughly clean the gearbox and the lubrication system to remove the metal particles from the system

- Carry out an inspection during the next stop to determine the progression of the bearing damage and the micropitting

- Adapt the lubrication system to provide the bearing pot with a higher volume flow of oil (or to consider the reverse mounting of the gearbox).

FLENDER KFO 630

Inspection and repair on FLENDER SVN280 gearbox

Scope of work:

- General disassembly and cleaning of all parts

- Inspect and report

- Go through the inspection report together during the work

- Assembly and testing

Scope of work:

- General disassembly and cleaning of all parts

- Inspect and report

- Go through the inspection report together during the work

- Assembly and testing

FLENDER SVN280

Inspection and repair on OSTERMANN KNV2-280R gearbox

OSTERMANN KNV2-280R

Inspection and repair on LOHMANN+STOLTERFOHT GWS 60.66 gearbox

The pitting on the gear theeth is most likely caused by corrosion.

Recommendations

- It is recommended to perform an annual visual inspection of the gearbox to define the progres-sivity of the micro pitting.

- A routine oil change is advised every 2000 serice hours, however, not longer than 12 months.

The pitting on the gear theeth is most likely caused by corrosion.

Recommendations

- It is recommended to perform an annual visual inspection of the gearbox to define the progres-sivity of the micro pitting.

- A routine oil change is advised every 2000 serice hours, however, not longer than 12 months.

LOHMANN STOLTERFOHT GWS 60.66

Inspection and repair on SEW FAF100LP132 gearbox

- Algehele demontage en schoonmaken van alle onderdelen.

- Inspecteren en rapporteren. (Stoppunt)

- Gezamenlijk bij het werk doornemen van het inspectierapport.

- Montage en beproeven

- Algehele demontage en schoonmaken van alle onderdelen.

- Inspecteren en rapporteren. (Stoppunt)

- Gezamenlijk bij het werk doornemen van het inspectierapport.

- Montage en beproeven

SEW FAF100LP132

Inspection and repair on SEW FAF100LP132 gearbox

- Algehele demontage en schoonmaken van alle onderdelen.

- Inspecteren en rapporteren.

- Gezamenlijk bij het werk doornemen van het inspectierapport.

- Montage en beproeven

- Algehele demontage en schoonmaken van alle onderdelen.

- Inspecteren en rapporteren.

- Gezamenlijk bij het werk doornemen van het inspectierapport.

- Montage en beproeven

SEW FAF100LP132

Inspection and repair on SAWA gearbox

The state of the gearbox can be considered unacceptable.

This conclusion based on:

- The wear on the bearings

- Tooth impression of the gear of the 1st axle

- The matt and gray discoloration

The wear on the bearings is probably due to the exceeding of the recommended running hours.

The tooth impression is as yet unknown. A further inspection will have to give a definite answer.

The matt and gray discoloration (pinion 3rd axis) is a sign of surface weakening, this is probably due to an over-angle bearing pattern of the tooth flanks, this is possible due to lower damage.

Recommendations

- Renew bearings

- Renew

The state of the gearbox can be considered unacceptable.

This conclusion based on:

- The wear on the bearings

- Tooth impression of the gear of the 1st axle

- The matt and gray discoloration

The wear on the bearings is probably due to the exceeding of the recommended running hours.

The tooth impression is as yet unknown. A further inspection will have to give a definite answer.

The matt and gray discoloration (pinion 3rd axis) is a sign of surface weakening, this is probably due to an over-angle bearing pattern of the tooth flanks, this is possible due to lower damage.

Recommendations

- Renew

SAWA

Inspection and repair on HANGZOU ADVANCE GEARBOX GWC6066 gearbox

Scope of work:

- Inspection Propulsion GBX, Hangzhou Advance GWC 6066

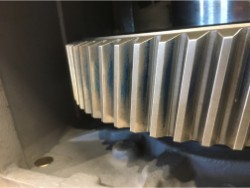

Micro pitting has been found on the following flanks:

- Intermediate shaft AHEAD gearwheel working flank (1st stage).

- Intermediate shaft AHEAD drum gear working flank (2nd stage).

The micro pitting is most likely formed in the last 2.5 months, the micro pitting could be initiated by small hard metal particles in the lubrication oil.

Micro pitting and in line pitting has been observed on the following flanks:

- Intermediate shaft AHEAD pinion working flank (3rd stage).

- Output shaft gearwheel working flank. AHEAD

Scope of work:

- Inspection Propulsion GBX, Hangzhou Advance GWC 6066

Micro pitting has been found on the following flanks:

- Intermediate shaft AHEAD gearwheel working flank (1st stage).

- Intermediate shaft AHEAD drum gear working flank (2nd stage).

The micro pitting is most likely formed in the last 2.5 months, the micro pitting could be initiated by small hard metal particles in the lubrication oil.

Micro pitting and in line pitting has been observed on the following flanks:

- Intermediate shaft AHEAD pinion working flank (3rd stage).

- Output shaft gearwheel working flank. AHEAD

HANGZOU ADVANCE GWC6066

Inspection and repair on RENK Aws 315 So gearbox

During the inspection, following observations were made:

- While using either the electric standby oil-pump or the mechanical oil-pump, lubrication oilpressure in pos. 43 is relatively low (0,4-0,8 [bar] respectively)

- The clutch control pressure in pos. 20 seems normal; circa 10,0-12,0 [bar] while both clutches are in disengaged (neutral) and 23,0-25,0 [bar] with either the forward or reverse clutch engaged.

- However, the clutch control pressure increases to 35,0 to 40,0 [bar] when both oil-pumps (standby and mechanical) are run simultaneously.

- The accumulating valve (pos. 30) was leaking oil, this was solved by replacing the o-rings inside the valve

During the inspection, following observations were made:

- While using either the electric standby oil-pump or the mechanical oil-pump, lubrication oilpressure in pos. 43 is relatively low (0,4-0,8 [bar] respectively)

- The clutch control pressure in pos. 20 seems normal; circa 10,0-12,0 [bar] while both clutches are in disengaged (neutral) and 23,0-25,0 [bar] with either the forward or reverse clutch engaged.

- However, the clutch control pressure increases to 35,0 to 40,0 [bar] when both oil-pumps (standby and mechanical) are run simultaneously.

- The accumulating valve (pos. 30) was leaking oil, this was solved by replacing the o-rings inside the valve

RENK Aws 315 So

Inspection and repair on ASUG GVE 800x3,75-800x0,4 gearbox

Scope of work:

- Inspection of all shaft, gears and bearings

- Inspection and disassembly of remaining parts

- Replacement of all roller bearings

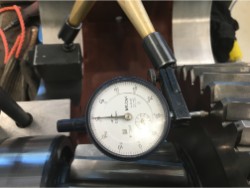

- Check of the axial clearance of all bearings

- Assembly of the gearbox on board the ship

- Assembly of the oil system

- Flushing of the gearbox

- Test run of the gearbox without

Scope of work:

- Inspection of all shaft, gears and bearings

- Inspection and disassembly of remaining parts

- Replacement of all roller bearings

- Check of the axial clearance of all bearings

- Assembly of the gearbox on board the ship

- Assembly of the oil system

- Flushing of the gearbox

- Test run of the gearbox without

ASUG GVE 800x3,75-800x0,4

Inspection and repair on CMD 28H30CTR gearbox

Scope of work:

- Dismantle of the gearbox

- Check the clearances and tooth contact pattern.

- Clean all gearbox related parts

- Measure the shaft and bore diameters.

Scope of work:

- Dismantle of the gearbox

- Check the clearances and tooth contact pattern.

- Clean all gearbox related parts

- Measure the shaft and bore diameters.

CMD 28H30CTR

Inspection and repair on FLENDER GCH 1020 gearbox

FLENDER GCH 1020

Inspection and repair on FLENDER G1-750VY gearbox

Scope of work:

- Inspection propulsion gearbox, Flender GA 845.

During inspection not, all bearings and gears could be inspected.

Small leakages were observed around the gearbox at the seals and on the OD-box.

The generator shaft bearings show wear, scratches and small indentations. The conditions of these bearings can be considered as non-acceptable.

Small steel particles were observed in the filter elements.

During the last oil sample there was found water inside the oil of the gearbox. Water in the oil can reduce the lifetime of the bearings and the gears.

Scope of work:

- Inspection propulsion gearbox, Flender GA 845.

During inspection not, all bearings and gears could be inspected.

Small leakages were observed around the gearbox at the seals and on the OD-box.

The generator shaft bearings show wear, scratches and small indentations. The conditions of these bearings can be considered as non-acceptable.

Small steel particles were observed in the filter elements.

During the last oil sample there was found water inside the oil of the gearbox. Water in the oil can reduce the lifetime of the bearings and the gears.

FLENDER G1-750VY

Inspection and repair on WGW gearbox

- Disassembly and assembly on location

- Disassembly, cleaning, inspection and assembly in shop GBS

- Test run including reporting in shop GBS

- Engineering

- Supply bearings, seals and various small materials

- Create a square set according to drawings

- Calculation of the gearbox by engineering

- Transport (collection and delivery)

- Disassembly and assembly on location

- Disassembly, cleaning, inspection and assembly in shop GBS

- Test run including reporting in shop GBS

- Engineering

- Supply bearings, seals and various small materials

- Create a square set according to drawings

- Calculation of the gearbox by engineering

- Transport (collection and delivery)

WGW UNKNOWN

Inspection and repair on JAHNEL-KESTERMANN gearbox

JAHNEL KESTERMANN

Inspection and repair on SCOLARI RM72 gearbox

Recommendations are:

- To continue annual visual inspections and biannual oil sample analysis

- To monitor the condition of the bearings closely during the next inspection considering the criticality of this machine to factory operations.

Recommendations are:

- To continue annual visual inspections and biannual oil sample analysis

- To monitor the condition of the bearings closely during the next inspection considering the criticality of this machine to factory operations.

SCOLARI RM72

Inspection and repair on HPM 455T099056 gearbox

HPM 455T099056

Inspection and repair on FLENDER 118F - 13,5 gearbox

Here is an overview of the work performed on the gearbox for the drive extruder. The gearbox was already completely overhauled by GBS in 2012. During a recent visual inspection, steel particles were found in the filter. The customer has therefore decided to expand the gearbox during a planned stop and have GBS inspected in the workshop. Furthermore, no other complaints were reported to the gearbox in advance. All seals were preventively renewed, bearings only in case of doubt.

The cause of the metal particles in the oil has been found and remedied.

It is recommended to:

- Take oil samples every six months and have them analyzed

- Carry out a visua

Here is an overview of the work performed on the gearbox for the drive extruder. The gearbox was already completely overhauled by GBS in 2012. During a recent visual inspection, steel particles were found in the filter. The customer has therefore decided to expand the gearbox during a planned stop and have GBS inspected in the workshop. Furthermore, no other complaints were reported to the gearbox in advance. All seals were preventively renewed, bearings only in case of doubt.

The cause of the metal particles in the oil has been found and remedied.

It is recommended to:

- Take oil samples every six months and have them analyzed

- Carry out a visua

FLENDER 118F - 13,5

Inspection and repair on HURTH HKS A 18-292 gearbox

The disassembly of the coupling went without problems. The condition of the coupling is 0.34 mm. After cleaning all parts it appeared that the return channel of the labyrinth was closed with silicone sealant, see photo 4. The return hole ends in the lower bolt hole of the labyrinth lid (This hole continues into the gearbox)

The suspicion of GBS is that some silicone sealant has been sprayed into the relevant bolt hole to prevent leakage of the screw thread, but too much is used so that the sealant is pushed backwards and thus has blocked the return hole. In consultation with the customer, and by telephone with their client, it was decided to carefully open the threaded hole,

The disassembly of the coupling went without problems. The condition of the coupling is 0.34 mm. After cleaning all parts it appeared that the return channel of the labyrinth was closed with silicone sealant, see photo 4. The return hole ends in the lower bolt hole of the labyrinth lid (This hole continues into the gearbox)

The suspicion of GBS is that some silicone sealant has been sprayed into the relevant bolt hole to prevent leakage of the screw thread, but too much is used so that the sealant is pushed backwards and thus has blocked the return hole. In consultation with the customer, and by telephone with their client, it was decided to carefully open the threaded hole,

HURTH HKS A 18-292

Inspection and repair on REXROTH GPV442.4 gearbox

Recommendations are:

-To perform an in-depth visual inspection of the planetary section of the gearbox in a wind situation that will allow manual pitching of the blades

v - To check the lubrication oil type and replace as stated in the last oil analysis report.

Recommendations are:

-To perform an in-depth visual inspection of the planetary section of the gearbox in a wind situation that will allow manual pitching of the blades

v - To check the lubrication oil type and replace as stated in the last oil analysis report.

REXROTH GPV442.4

Inspection and repair on REXROTH GPV442.4 gearbox

Recommendations are:

- To perform an in-depth inspection of the FE bearing of the generator by additional vibration measurements (after checking the grease supply to the bearing)

- To perform annual visual inspections and oil analyses.

Recommendations are:

- To perform an in-depth inspection of the FE bearing of the generator by additional vibration measurements (after checking the grease supply to the bearing)

- To perform annual visual inspections and oil analyses.

REXROTH GPV442.4